Folks,

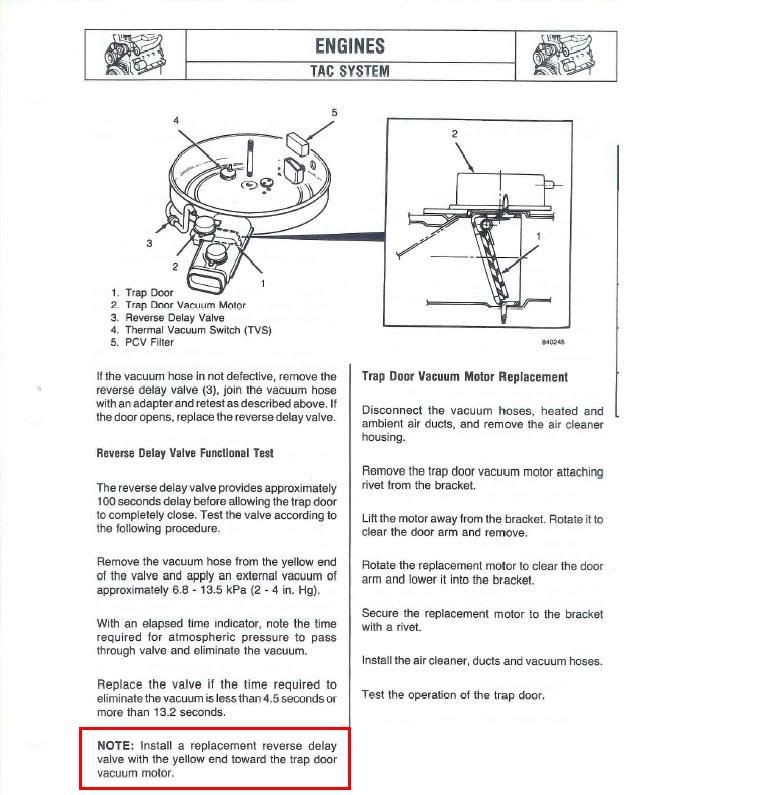

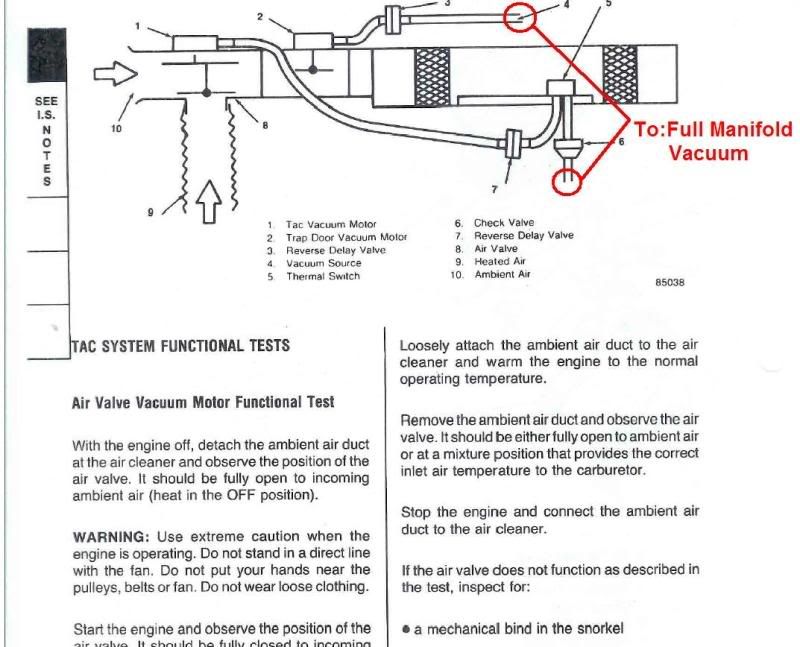

What is the REAL purpose of this gadget (TAC) and is it supposed to have a tiny ball bearing inside the rubber hose line between the Delay Valve and Air Door on the air filter?

I ask because that tiny 4"-5" hose was in need of replacement (dried out/cracked) and when I went to blow through it, I couldn't. When I looked through the small rubber hose line, I noticed it had a tiny little ball bearing that was blocking the air flow. The Jeep has been running real good with it but maybe it wasn't?

Anyway, I replaced the small rubber hose line and kept the ball bearing OUT. It seems to be running real good so AM I MISSING SOMETHING HERE? Why would it be there?

What is the REAL purpose of this gadget (TAC) and is it supposed to have a tiny ball bearing inside the rubber hose line between the Delay Valve and Air Door on the air filter?

I ask because that tiny 4"-5" hose was in need of replacement (dried out/cracked) and when I went to blow through it, I couldn't. When I looked through the small rubber hose line, I noticed it had a tiny little ball bearing that was blocking the air flow. The Jeep has been running real good with it but maybe it wasn't?

Anyway, I replaced the small rubber hose line and kept the ball bearing OUT. It seems to be running real good so AM I MISSING SOMETHING HERE? Why would it be there?