So i have a 2005 wrangler 4.0l with about 58k miles. I put on a body lift and then a mml and before i removed the transfer case drop i went to turn it on and it struggled to turn on but did turn on and idled fine, and when i would restart it it would turn on fine without hesitation.

I didn't think much of it but the next day i removed my transfer case drop and was going to go for a test drive to check for vibes. Once again it struggled to turn on the first time and after a few min of driving it i get a check engine light and the P0016 code comes up and my jeep would not rev past about 3200 rpms.

So i start searching around and i start with looking at my crank position sensor and my cam position sensor to see if i did any damage when i did the mml. The cam position sensor had some damage to it almost as if i smashed the wires....

![Image]()

I then look into finding my crank position sensor, some say its on top of the bell housing, some say its on the passenger side, so quite honestly i don't know what i'm looking for, but judging by the looks of the replacement crank sensor i'm guessing its the one on the passenger side with the 90 degree turn but ill post pics of both just in case i'm wrong and to see if you guys can spot anything out of the ordinary...

![Image]()

![Image]()

![Image]()

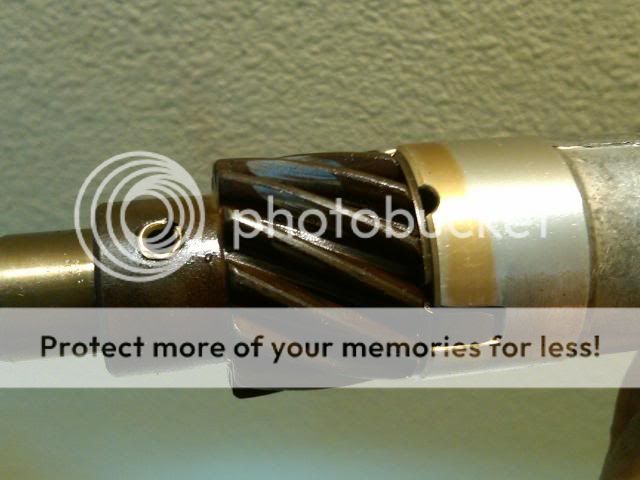

I then started reading the threads about the whole can of worms going on with the OPDA. I never had any problems with it before and i was certain it had to do something with the mml. But i took it off to inspect it anyways just to not leave any stones unturned. To me it doesn't look that bad. Just a little discoloration but nothing compared to the ones ive seen in those other threads....

![Image]()

![Image]()

So i need your guys help on what i should do here? whats my first move?

replace the cam sensor? crank sensor? does it have anything to do with timing? what about something about the ECM needing to relearn the sensors?

if you guys have any questions or need any more pictures just let me know

thanks

I didn't think much of it but the next day i removed my transfer case drop and was going to go for a test drive to check for vibes. Once again it struggled to turn on the first time and after a few min of driving it i get a check engine light and the P0016 code comes up and my jeep would not rev past about 3200 rpms.

So i start searching around and i start with looking at my crank position sensor and my cam position sensor to see if i did any damage when i did the mml. The cam position sensor had some damage to it almost as if i smashed the wires....

I then look into finding my crank position sensor, some say its on top of the bell housing, some say its on the passenger side, so quite honestly i don't know what i'm looking for, but judging by the looks of the replacement crank sensor i'm guessing its the one on the passenger side with the 90 degree turn but ill post pics of both just in case i'm wrong and to see if you guys can spot anything out of the ordinary...

I then started reading the threads about the whole can of worms going on with the OPDA. I never had any problems with it before and i was certain it had to do something with the mml. But i took it off to inspect it anyways just to not leave any stones unturned. To me it doesn't look that bad. Just a little discoloration but nothing compared to the ones ive seen in those other threads....

So i need your guys help on what i should do here? whats my first move?

replace the cam sensor? crank sensor? does it have anything to do with timing? what about something about the ECM needing to relearn the sensors?

if you guys have any questions or need any more pictures just let me know

thanks