How To Build a PVC Intake for a 3.7L V6 Grand Cherokee

Parts

- About 2' of 3'' diameter PVC pipe

- 1 45˚ elbow for 3'' pipe

- 1 90˚ elbow for 3'' pipe

- High Flow Intake Filter (I used Spectre)

- Duct Tape

- PVC Cement

In total it cost me right around $50 to make! That's $20 less than the K&N filter (not the whole intake) I was looking at alone!

Tools

- Saw to cut PVC pipe and stock hose coupler

- 5/32 alan wrench (best if on an extended screwdriver)

- Flat head screwdriver to remove the air box

- Scissors to cut tape

- Drill bit to drill the air intake sensor hole

- Lighter to melt the duct tape air tight

- Sharpie

![Image]()

Started by removing the stock intake hose. Just loosen the clamps on both ends.

![Image]()

Then removed the air intake sensor (correct term?). Twist and pull out.

![Image]()

Then loosened the clamp on the throttle body behind the air box.

![Image]()

Used a 5/32 alan wrench to get the right side of the air box off. Very tight spot - recommend using an extended screwdriver bit as I had to buy one anyways to reach the left side.

Right:

![Image]()

Right:

![Image]()

Left:

![Image]()

Once the clamps and both screws are removed the air box may be removed. Just had to shift it around different ways until it squeezed out.

![Image]()

Remove the top of the stock filter box. Pull off the hose.

![Image]()

Tested the unfinished piping and filter to get an idea of placement and sound.

![Image]()

Had to cut 5 inches off the end of the 2' tube.

![Image]()

Cut the end of the stock intake hose to use as a coupler for the elbow to the throttle body. Used duct tape to connect the coupler to the pipe. Used a lighter to melt the tape to an airtight seal.

![Image]()

Test fitted the pipe. Used the 5'' piece cut off earlier to connect the 45˚ elbow to the 90˚ elbow which will connect to the throttle body via the coupler made from the stock hose.

![Image]()

Once I found the correct angle for the pieces to connect I used a sharpie to draw guidance lines. Then used PVC cement to stick all the pieces together.

![Image]()

Drilled a hole for the air intake sensor to fit in. Once finished drilling I used a Swiffer cloth on the end of a pole to clean out the inside of the pipe, then blew it out with a shopvac and vacuumed after that. Don't want any shavings getting into the engine.

![Image]()

By now it is obvious - this thing is ghetto rigged. To top it all off I duct taped a sponge up and zip-tied it in place to support the pipe.

![Image]()

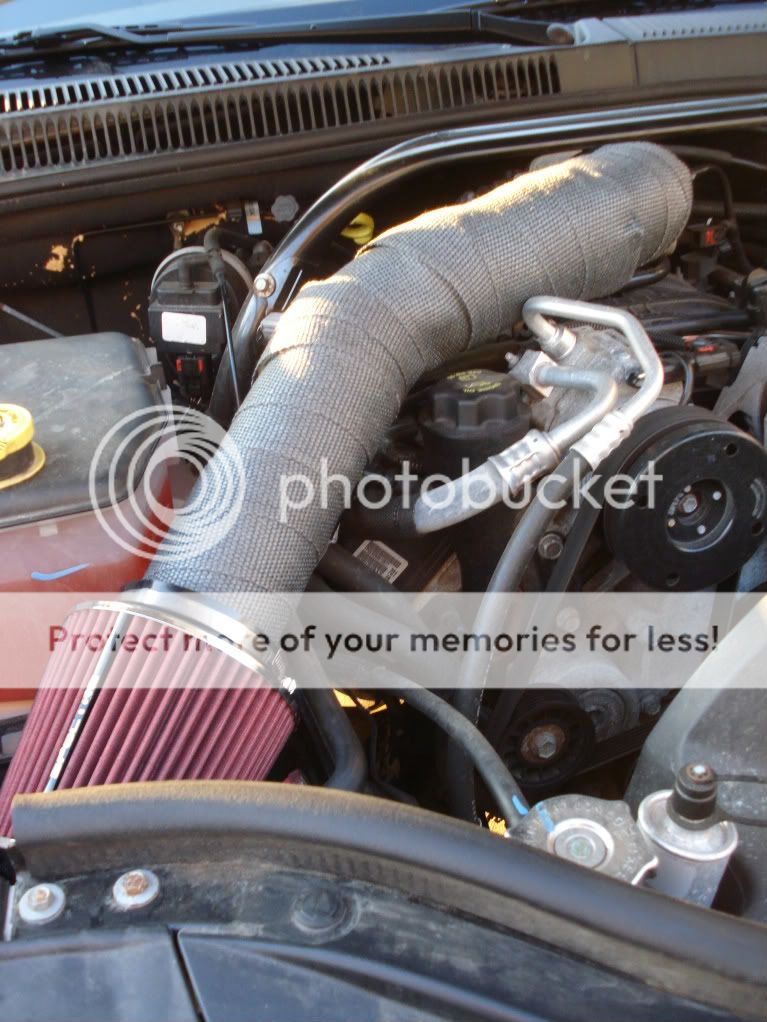

A view of the pipe. 90˚ elbow with the coupler on the end, to the 5'' straight pipe, to the 45˚ elbow, to the remaining straight pipe (had to cut off more to get it to fit right. Ended up protruding from the 45˚ 8 inches).

![Image]()

Installed it. Tightened the clamp to the throttle body and the one on the filter. Plugged the air intake sensor into the drilled hole. Made sure everything was snug and took it for a test run! Runs great! Instant reaction when I push on the gas. Much quicker acceleration. Definitely feel a noticeable difference. Will be keeping an eye on the MPG changes.

![Image]()

I plan to remove the pipe to spray paint it as soon as I get the chance.

Parts

- About 2' of 3'' diameter PVC pipe

- 1 45˚ elbow for 3'' pipe

- 1 90˚ elbow for 3'' pipe

- High Flow Intake Filter (I used Spectre)

- Duct Tape

- PVC Cement

In total it cost me right around $50 to make! That's $20 less than the K&N filter (not the whole intake) I was looking at alone!

Tools

- Saw to cut PVC pipe and stock hose coupler

- 5/32 alan wrench (best if on an extended screwdriver)

- Flat head screwdriver to remove the air box

- Scissors to cut tape

- Drill bit to drill the air intake sensor hole

- Lighter to melt the duct tape air tight

- Sharpie

Started by removing the stock intake hose. Just loosen the clamps on both ends.

Then removed the air intake sensor (correct term?). Twist and pull out.

Then loosened the clamp on the throttle body behind the air box.

Used a 5/32 alan wrench to get the right side of the air box off. Very tight spot - recommend using an extended screwdriver bit as I had to buy one anyways to reach the left side.

Right:

Right:

Left:

Once the clamps and both screws are removed the air box may be removed. Just had to shift it around different ways until it squeezed out.

Remove the top of the stock filter box. Pull off the hose.

Tested the unfinished piping and filter to get an idea of placement and sound.

Had to cut 5 inches off the end of the 2' tube.

Cut the end of the stock intake hose to use as a coupler for the elbow to the throttle body. Used duct tape to connect the coupler to the pipe. Used a lighter to melt the tape to an airtight seal.

Test fitted the pipe. Used the 5'' piece cut off earlier to connect the 45˚ elbow to the 90˚ elbow which will connect to the throttle body via the coupler made from the stock hose.

Once I found the correct angle for the pieces to connect I used a sharpie to draw guidance lines. Then used PVC cement to stick all the pieces together.

Drilled a hole for the air intake sensor to fit in. Once finished drilling I used a Swiffer cloth on the end of a pole to clean out the inside of the pipe, then blew it out with a shopvac and vacuumed after that. Don't want any shavings getting into the engine.

By now it is obvious - this thing is ghetto rigged. To top it all off I duct taped a sponge up and zip-tied it in place to support the pipe.

A view of the pipe. 90˚ elbow with the coupler on the end, to the 5'' straight pipe, to the 45˚ elbow, to the remaining straight pipe (had to cut off more to get it to fit right. Ended up protruding from the 45˚ 8 inches).

Installed it. Tightened the clamp to the throttle body and the one on the filter. Plugged the air intake sensor into the drilled hole. Made sure everything was snug and took it for a test run! Runs great! Instant reaction when I push on the gas. Much quicker acceleration. Definitely feel a noticeable difference. Will be keeping an eye on the MPG changes.

I plan to remove the pipe to spray paint it as soon as I get the chance.