Hey all!

Long time no talk... I've been on JF for a long, long, long time since before I purchased my TJ a decade ago, but haven't remained as active over the past few years. So this is my formal re-introduction with a new build. I write an endurance adventure blog that with stories of my Appalachian Trail thru-hike, cross country bicycle trip, and recent attempt at Vermont's 273 mile Long Trail over two weeks last month. Disappointed that one ended early, but you can go read about it and see photos if you'd like: www.2180miles.com

Some of you might remember Big Red from a ways back... She's up on 35" MTR/Ks, 3" lift with Currie suspension components, 8k winch, Undercover Fab aluminum skids from front to back, Rigid LEDs everywhere, strobe lights for on-road recovery stuff (good samaritan lights as I call them) and the rest of the typical works with electronics and radios. The members of the Massachusetts Jeep club I founded in 2011 affectionately call her Big Red. As our club has grown, my close group of Jeep friends began discussing an overland trip through northern New England. As I took on the planning of our adventure with my buddy Rob, I began realizing that the TJ wasn't going to be the best platform for me personally to do these kinds of trips in.

I began shopping for a JKUR, floating the idea of trading my daily driver in and keeping the TJ and the JKUR, each to serve different purposes. As my research continued and I spoke with JKUR owner friends, I realized that I'd much rather have something along the lines of an SUV that would be less of a one trick pony. I travel for work and therefore frequently have rental cars, so I began test driving the Grand Cherokees during my weeks away from home, which ultimately turned my search in that direction. Reading about the current (2016) and new models for 2017, I focused on the Overland and Trailhawk trims as ones I'd be interested in buying. Price was a factor, but I knew early on that I didn't want to heavily mod this truck, so buying a Limited trim and upgrading things wasn't really in the cards for me. The Overland is much more of a luxury oriented vehicle than the name might suggest, and the Trailhawk is the nitty gritty, but still very well equipped, model.

After many months of waiting, debating, test driving, yada yada, I finally went ahead and purchased a 2017 Trailhawk last week. Fully loaded (minus Blu-Ray entertainment), it was a unique package with the active safety package, luxury package - read: panoramic sunroof that I dreamed about, multiple skid plates underneath, 18" wheels wrapped in Kevlar lined Goodyear A/Ts, and the Quadra-Trac/air suspension package. Sticker was $49,500, and after a week of putting dealerships against each other, and after a bit of negotiating I got it from a dealer in New Hampshire (90 minutes from my house in Boston), for $42,799. I am quite happy with the price, and opted to add the 7-year bumper to bumper Mopar warranty for $1,300 for a piece of mind. There's a high likelihood I keep it that long, and I can get money back from FCA if I sell the vehicle first.

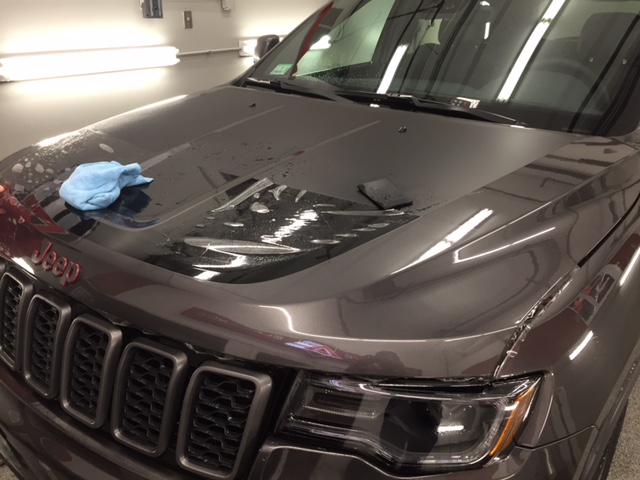

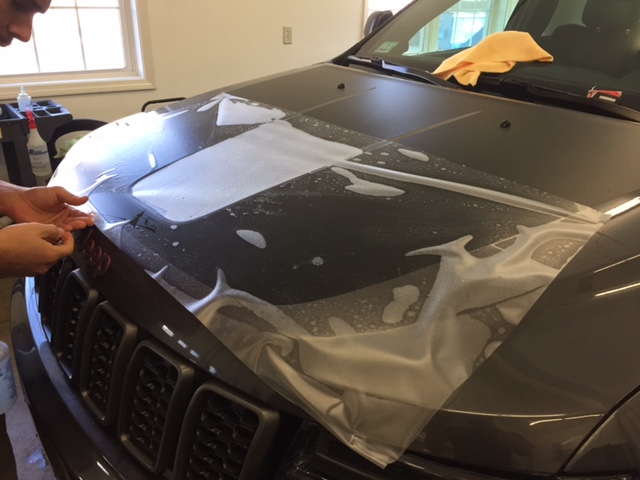

I purchased it and dropped it off immediately for the front end to be protective wrapped, so I didn't have a chance to take it for a real high-res photo shoot (save for lining the ladies up for a family photo as you'll see below). Here are some photos to start, since that's what we all love in these threads anyway. This will not be the most advanced or capable build in the history of this forum, but aside the rare iPhone photo, I promise to at least have high quality pictures.

Look forward to writing more posts with mods and adventures.

Ryan

At the Dealership by Ryan McKee

Three's Company by Ryan McKee

Long time no talk... I've been on JF for a long, long, long time since before I purchased my TJ a decade ago, but haven't remained as active over the past few years. So this is my formal re-introduction with a new build. I write an endurance adventure blog that with stories of my Appalachian Trail thru-hike, cross country bicycle trip, and recent attempt at Vermont's 273 mile Long Trail over two weeks last month. Disappointed that one ended early, but you can go read about it and see photos if you'd like: www.2180miles.com

Some of you might remember Big Red from a ways back... She's up on 35" MTR/Ks, 3" lift with Currie suspension components, 8k winch, Undercover Fab aluminum skids from front to back, Rigid LEDs everywhere, strobe lights for on-road recovery stuff (good samaritan lights as I call them) and the rest of the typical works with electronics and radios. The members of the Massachusetts Jeep club I founded in 2011 affectionately call her Big Red. As our club has grown, my close group of Jeep friends began discussing an overland trip through northern New England. As I took on the planning of our adventure with my buddy Rob, I began realizing that the TJ wasn't going to be the best platform for me personally to do these kinds of trips in.

I began shopping for a JKUR, floating the idea of trading my daily driver in and keeping the TJ and the JKUR, each to serve different purposes. As my research continued and I spoke with JKUR owner friends, I realized that I'd much rather have something along the lines of an SUV that would be less of a one trick pony. I travel for work and therefore frequently have rental cars, so I began test driving the Grand Cherokees during my weeks away from home, which ultimately turned my search in that direction. Reading about the current (2016) and new models for 2017, I focused on the Overland and Trailhawk trims as ones I'd be interested in buying. Price was a factor, but I knew early on that I didn't want to heavily mod this truck, so buying a Limited trim and upgrading things wasn't really in the cards for me. The Overland is much more of a luxury oriented vehicle than the name might suggest, and the Trailhawk is the nitty gritty, but still very well equipped, model.

After many months of waiting, debating, test driving, yada yada, I finally went ahead and purchased a 2017 Trailhawk last week. Fully loaded (minus Blu-Ray entertainment), it was a unique package with the active safety package, luxury package - read: panoramic sunroof that I dreamed about, multiple skid plates underneath, 18" wheels wrapped in Kevlar lined Goodyear A/Ts, and the Quadra-Trac/air suspension package. Sticker was $49,500, and after a week of putting dealerships against each other, and after a bit of negotiating I got it from a dealer in New Hampshire (90 minutes from my house in Boston), for $42,799. I am quite happy with the price, and opted to add the 7-year bumper to bumper Mopar warranty for $1,300 for a piece of mind. There's a high likelihood I keep it that long, and I can get money back from FCA if I sell the vehicle first.

I purchased it and dropped it off immediately for the front end to be protective wrapped, so I didn't have a chance to take it for a real high-res photo shoot (save for lining the ladies up for a family photo as you'll see below). Here are some photos to start, since that's what we all love in these threads anyway. This will not be the most advanced or capable build in the history of this forum, but aside the rare iPhone photo, I promise to at least have high quality pictures.

Look forward to writing more posts with mods and adventures.

Ryan

At the Dealership by Ryan McKee

Three's Company by Ryan McKee