I drove to work, while setting my 08'KK in park the shifter went into park and the car stayed in neutral. I am mechanically inclined, but have never crossed anything like this. I need ideas as to how I can see if it is my cable or I broke something in the plastic shifter housing. I got underneath the kk and I cannot shift it into park from the bottom of the cable. I can move the cable freely into any other position while under the KK. While I press the brake the shifter will not move until I popped the small hole that I can then place a screwdriver in and press the lever to bring the shifter out of park. I cannot find any videos online as to how to troubleshoot or repair the KK. I believe the solenoid/plunger on the cable that releases the shifter when the brake is pressed has gone bad. Not sure if that is possible.Need any help that can be given. Thank you.

LanceC

Shifter or Cable???

1 reading

LanceC

Discussion starter

1 post

·

Joined 2021

- Add to quote Only show this user

I drove to work, while setting my 08'KK in park the shifter went into park and the car stayed in neutral. I am mechanically inclined, but have never crossed anything like this. I need ideas as to how I can see if it is my cable or I broke something in the plastic shifter housing. I got underneath the kk and I cannot shift it into park from the bottom of the cable. I can move the cable freely into any other position while under the KK. While I press the brake the shifter will not move until I popped the small hole that I can then place a screwdriver in and press the lever to bring the shifter out of park. I cannot find any videos online as to how to troubleshoot or repair the KK. I believe the solenoid/plunger on the cable that releases the shifter when the brake is pressed has gone bad. Not sure if that is possible.Need any help that can be given. Thank you.

23,907 posts

·

Joined 2009

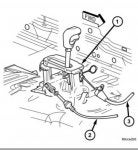

Gearshift Adjustment Procedure

1. Shift transmission into PARK.

2. Remove floor console as necessary for access to the shift cable adjustment.

3. Loosen the shift cable adjustment screw.

4. Raise vehicle.

5. Unsnap cable eyelet from transmission shift lever.

6. Verify transmission shift lever is in PARK detent by moving lever fully rearward. Last rearward detent is PARK position.

7. Verify positive engagement of transmission park lock by attempting to rotate propeller shaft. Shaft will not rotate when park lock is engaged.

8. Snap cable eyelet onto transmission shift lever.

9. Lower vehicle

10. Tighten the shift cable adjustment screw to 7 N·m (65 in.lbs.).

11. Verify correct operation.

12. Install any floor console components removed for access.

1. Shift transmission into PARK.

2. Remove floor console as necessary for access to the shift cable adjustment.

3. Loosen the shift cable adjustment screw.

4. Raise vehicle.

5. Unsnap cable eyelet from transmission shift lever.

6. Verify transmission shift lever is in PARK detent by moving lever fully rearward. Last rearward detent is PARK position.

7. Verify positive engagement of transmission park lock by attempting to rotate propeller shaft. Shaft will not rotate when park lock is engaged.

8. Snap cable eyelet onto transmission shift lever.

9. Lower vehicle

10. Tighten the shift cable adjustment screw to 7 N·m (65 in.lbs.).

11. Verify correct operation.

12. Install any floor console components removed for access.

Attachments

-

63.2 KB Views: 124

23,907 posts

·

Joined 2009

The automatic transmission is operated with the help of a shift lever assembly (SLA) located in the floor console. There are six positions to which the selection lever can be shifted: Park, Reverse, Neutral, Drive, Manual Second, Manual Low. The selector lever positions ""P"", ""R"", ""N"" ""D"" ""2"" and ""1"" are transmitted by a shift cable to the selector shaft in the transmission, indication in cluster.

•Park (P)

•Reverse (R)

•Neutral (N)

•Drive (D)

•Manual second (2)

•Manual low (1)

The SLA is comprised of the following functions.

Key lock

Depending on the selector lever position, the ignition cylinder is locked/unlocked, i.e., the ignition key can be removed only if the selector lever is in position "P", and the shift lever can be moved out of "P" only after the key has been turned clockwise from LOCK (1) position. A park lock cable is used to perform this functions.

Park lock

The selector lever is not released from postion "P" until the brake pedal has been applied and the ignition key is in ON (3) position. Shift lock is controlled by the brake light switch in conjunction with a locking solenoid in the SLA. As soon as the brake pedal is applied, the locking solenoid is energized and retracted to unlock the selector lever. If the selector lever cannot be moved out of position "P" due to a malfunction, the shift lock function can be overriden.

ADJUSTMENTS - park lock The interlock cable connects the lock housing and the ATX shifter. The shifter is locked until the key cylinder is rotated clockwise from the LOCK (1) position. Once the key cylinder is rotated out of LOCK (1), the shifter may be moved from Park. As the shifter moved from Park, the interlock cable is held at a position that prevents key removal.

1. Remove floor console as necessary for access to the park-interlock cable.

2. Make sure the shifer is in PARK position.

3. Un-snap the cable end fitting from shifter base reaction bracket.

4. Attempt to take out the key from ignition cylinder moving the core cable fore/aft.

5. With the key removed from cylinder, un-snap the locking tab from cable end-fitting.

6. Slide back in the cable end-fitting onto shifter base reaction bracket.

7. Push in the locking tab until fully seated - the top surface must be under flash relatively to cylinder end-fitting and both sides snapped over the locking features.

8. Verify proper operation.

9. Install the floor console.

•Park (P)

•Reverse (R)

•Neutral (N)

•Drive (D)

•Manual second (2)

•Manual low (1)

The SLA is comprised of the following functions.

Key lock

Depending on the selector lever position, the ignition cylinder is locked/unlocked, i.e., the ignition key can be removed only if the selector lever is in position "P", and the shift lever can be moved out of "P" only after the key has been turned clockwise from LOCK (1) position. A park lock cable is used to perform this functions.

Park lock

The selector lever is not released from postion "P" until the brake pedal has been applied and the ignition key is in ON (3) position. Shift lock is controlled by the brake light switch in conjunction with a locking solenoid in the SLA. As soon as the brake pedal is applied, the locking solenoid is energized and retracted to unlock the selector lever. If the selector lever cannot be moved out of position "P" due to a malfunction, the shift lock function can be overriden.

ADJUSTMENTS - park lock The interlock cable connects the lock housing and the ATX shifter. The shifter is locked until the key cylinder is rotated clockwise from the LOCK (1) position. Once the key cylinder is rotated out of LOCK (1), the shifter may be moved from Park. As the shifter moved from Park, the interlock cable is held at a position that prevents key removal.

1. Remove floor console as necessary for access to the park-interlock cable.

2. Make sure the shifer is in PARK position.

3. Un-snap the cable end fitting from shifter base reaction bracket.

4. Attempt to take out the key from ignition cylinder moving the core cable fore/aft.

5. With the key removed from cylinder, un-snap the locking tab from cable end-fitting.

6. Slide back in the cable end-fitting onto shifter base reaction bracket.

7. Push in the locking tab until fully seated - the top surface must be under flash relatively to cylinder end-fitting and both sides snapped over the locking features.

8. Verify proper operation.

9. Install the floor console.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 19M

- members

- 766K

- Since

- 2000

A forum community dedicated to all jeep owners and enthusiasts. Come join the discussion about performance, engine swaps, modifications, classifieds, troubleshooting, maintenance, and more!