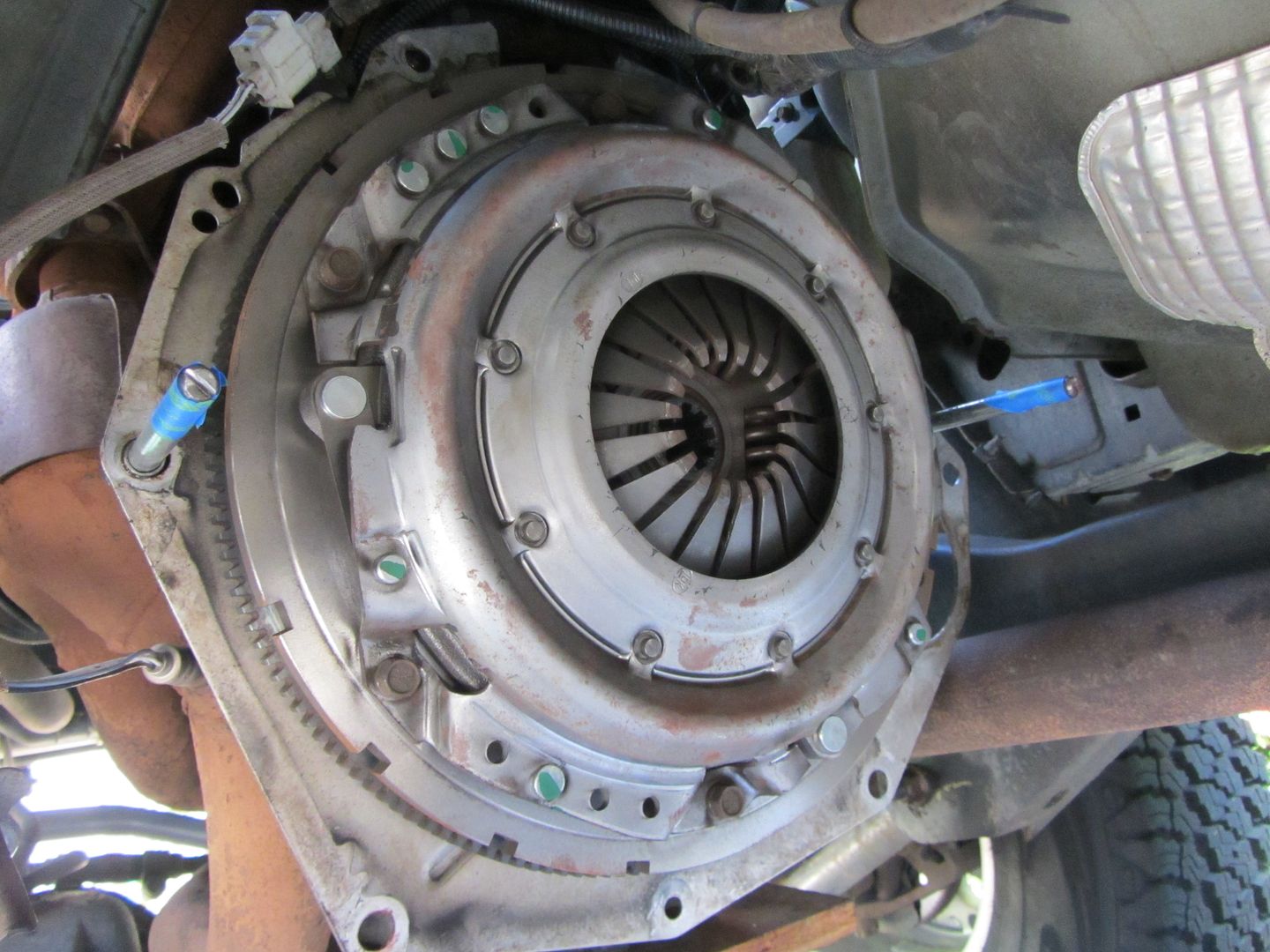

Did clutch and now I'm having a huge issue of getting the transmission back on.

Had so much trouble I took the transfer case off to aid in maneuverability. I've got it on a pretty good transmission jack.

I can get the input shaft angled into the clutch fingers, then tilt it up to get it what is, as far as I can tell, parallel to the flywheel surface. Then I move it a few inches in, and it just stops. At this point I have lost sight of the input shaft and I can't tell where I'm hanging up.

Input is appreciated.

![Image]()

Had so much trouble I took the transfer case off to aid in maneuverability. I've got it on a pretty good transmission jack.

I can get the input shaft angled into the clutch fingers, then tilt it up to get it what is, as far as I can tell, parallel to the flywheel surface. Then I move it a few inches in, and it just stops. At this point I have lost sight of the input shaft and I can't tell where I'm hanging up.

Input is appreciated.