What tips and tricks have people come up with to mount the Ford Contour fan to a CJ7 radiator?

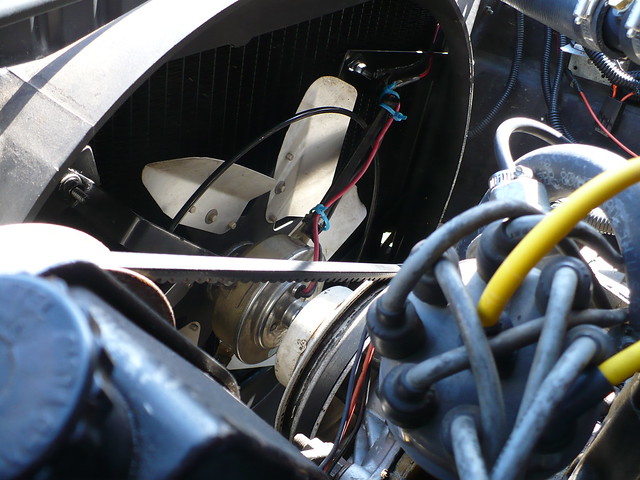

Some people have used the plastic ties that go through the radiator but I am not sure this is the best solution for a 4X4.

I have seen where some people mount brackets to the left and right sides of the shroud when mounting the fan on other types of vehicles but the CJ7 so close on the width that there is probably not enough room. I like this solution but am not sure how to make it work with the CJ7.

I would like to replace the bolts that hold the radiator I with all-thread that has a nut locktited in the correct positon so that a stud is sticking out of the back side of the nut and the stud can be used to mount the fan frame.

Please show me your well engineered mounting solutions.

Thanks...

Some people have used the plastic ties that go through the radiator but I am not sure this is the best solution for a 4X4.

I have seen where some people mount brackets to the left and right sides of the shroud when mounting the fan on other types of vehicles but the CJ7 so close on the width that there is probably not enough room. I like this solution but am not sure how to make it work with the CJ7.

I would like to replace the bolts that hold the radiator I with all-thread that has a nut locktited in the correct positon so that a stud is sticking out of the back side of the nut and the stud can be used to mount the fan frame.

Please show me your well engineered mounting solutions.

Thanks...