1997 Cherokee.

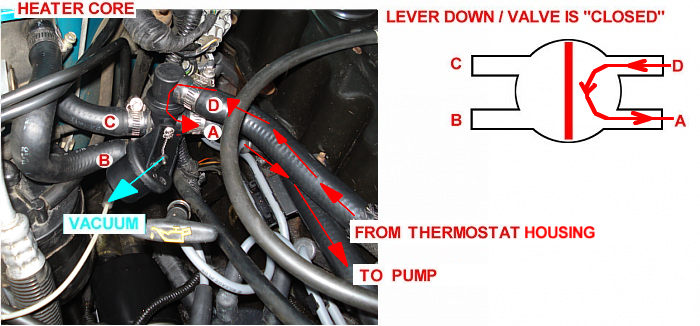

Which is under pressure? The one coming off the water pump, the one coming off thermostat housing?

Yes it seems like a no brainer but want to check.

Which is under pressure? The one coming off the water pump, the one coming off thermostat housing?

Yes it seems like a no brainer but want to check.